Decanter centrifuge lubrication is probably the most important part of all maintenance. For each decanter all lubrication points are shown in the instruction manual and the recommended lubrication interval as well as amount and type of lubricant is stated. Most decanter centrifuge have grease lubricated main bearings, scroll conveyor bearings, and oil lubricated gearboxes.

Rigorous maintenance and service is essential for every decanter centrifuge. properly grease decanter bearings makes it the obvious choice for increasing the lifetime of machinery and avoiding costly maintenance and repairs.

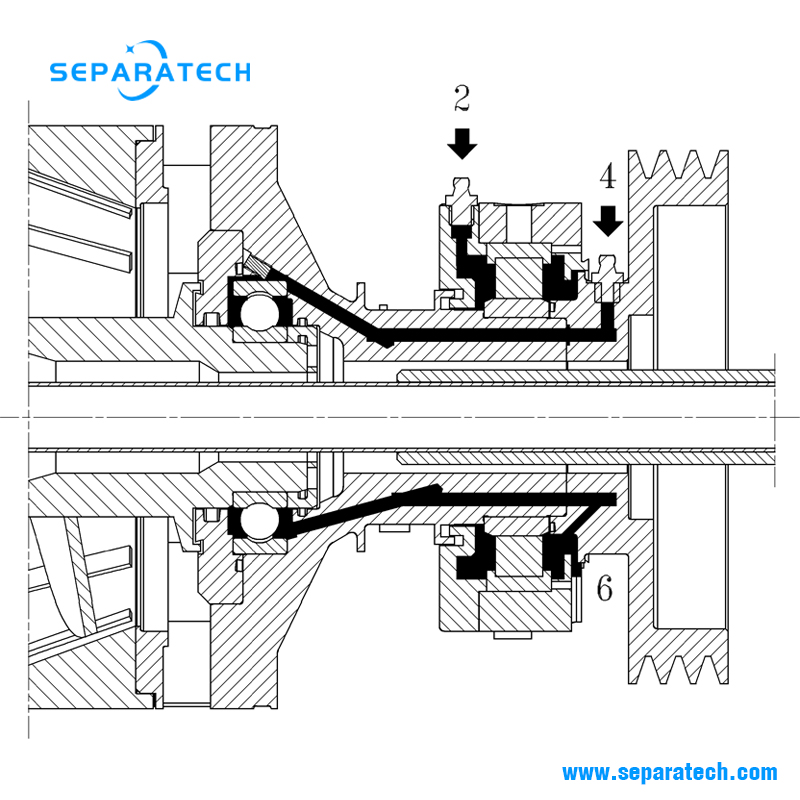

Main bearings lubrication

Decanter centrifuge lubrication for main bearings carried out while the decanter centrifuge is running, and preferably, just before stopping it for any prolonged period of time.

This will ensure the best distribution of grease, which in its turn gives optimum lubrication condition and maximum protection against contamination of the bearings.

If the decanter is taken out of service for a certain period every week, lubricate the main bearings just before stopping the decanter.

If the decanter is taken out of service for more than two weeks, its main bearings must be lubricated every two weeks during the inactive period.

Using the grease gun included in the standard decanter delivery, apply some of grease to each bearing. The amount of grease filled can refer to the operation manual. Then turn the bowl slowly by hand.

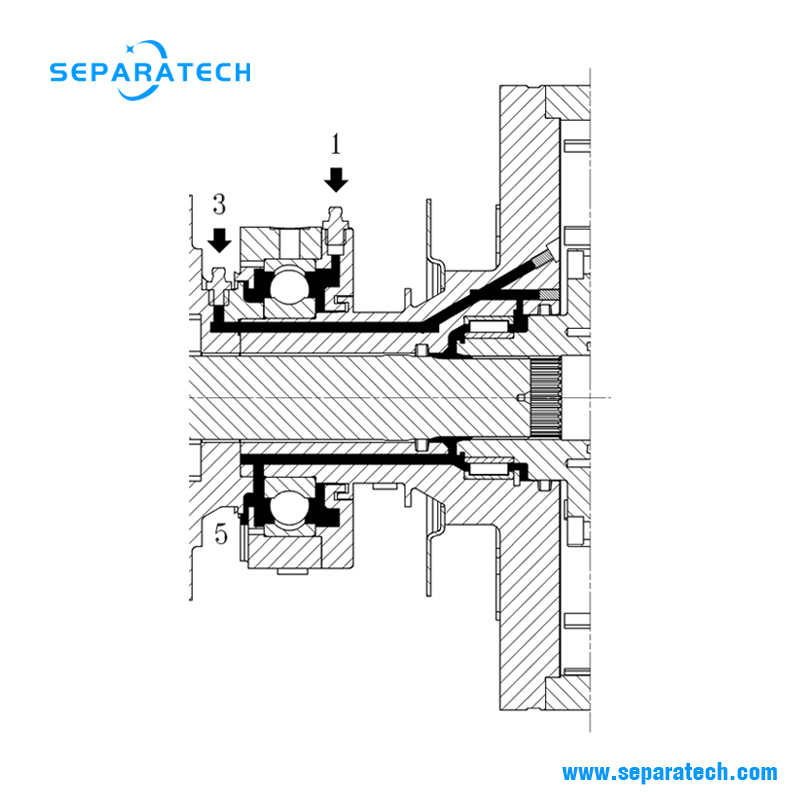

Scroll conveyor bearings lubrication

Decanter centrifuge lubrication for scroll conveyor bearings implemented when the decanter centrifuge stopped and the power effectively disconnected from the main motor.

Using the grease gun included in the standard decanter delivery, apply some grease to each bearing. The amount of grease filled can refer to the operation manual.

For decanters operating with feed temperatures above 90°C (200°F), the lubrication interval shall be shortened.

If the decanter is cleaned with low speed CIP, it is recommended to lubricate the conveyor bearings after the low speed. The quantity of grease shall be reduced according to the number of operating hours between each low speed CIP.