Edible oil refining

Edible oil refining, which is a set of processes or treatments necessary to turn vegetable raw oil into edible oil. Edible oil refining removes impurities, such as free fatty acids, phospholipids, waxes, pigments, and odors, that can affect the quality, flavor, and shelf life of the oil. The steps for refining edible oil are :

– Neutralization: Oil heated to 85 ºC and combined with an alkaline substance to neutralize the free fatty acids and form soapstock.

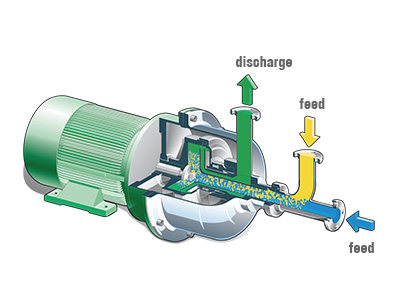

– Degumming: Oil treated with water or acid and gum dregs removed by centrifugation or filtration. This step eliminates the natural emulsifiers that can increase the viscosity of the oil.

– Bleaching: Oil mixed with bleaching earth, such as TONSIL®, to adsorb the pigments and other impurities. The bleaching earth is then filtered out by presses.

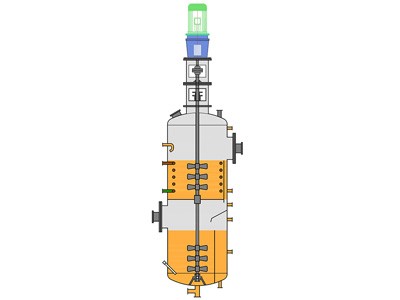

– Deodorization: Oil heated to high temperature and steam passed through it to remove the volatile compounds that cause unpleasant odors and flavors.

The type and degree of refining depends on the source and quality of the raw oil. Some oils, such as coconut and palm oil, require less degumming than others, such as soybean and rapeseed oil. Some oils may also undergo additional processes, such as winterization, fractionation, or hydrogenation, to modify their physical or chemical properties.