high-efficiency bleaching reactor for edible oil refining

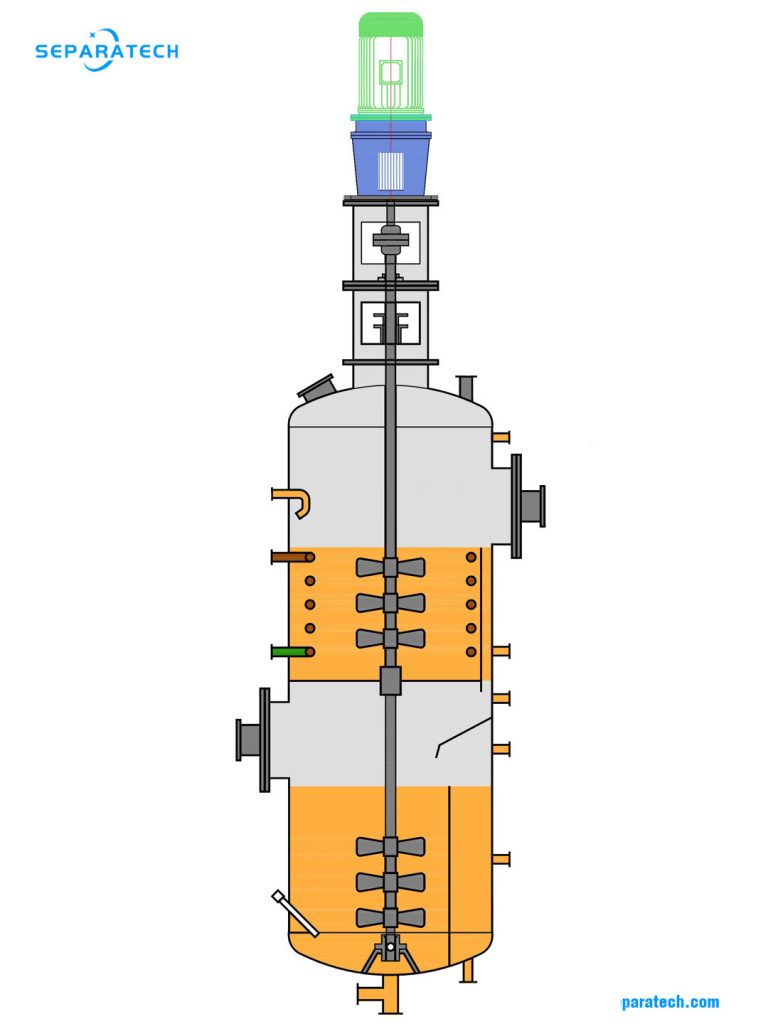

SEPARATECH’s bleaching reactor is specifically designed to optimize the bleaching process in edible oil refining. The bleaching reactor features a unique design that includes a heating jacket, agitator, and filtration system. The heating jacket ensures precise temperature control during the heating stage, while the agitator ensures even distribution of the bleaching earth in the oil. The filtration system is designed to remove the bleaching earth efficiently from the oil.

SEPARATECH’s bleaching reactor also features a tray for bleaching earth loading and unloading. This design allows for easy and efficient loading and unloading of bleaching earth, reducing downtime and increasing productivity. The bleaching reactor is also easy to clean and maintain, ensuring a hygienic and safe processing environment.

SEPARATECH’s bleaching reactor is also equipped with a prefiltration system that allows the feed oil to pass through a saturated filter before mixing it with fresh clay. This technique reduces clay consumption and improves bleaching efficiency. The prefiltration system works only with dry oils, so it is not suitable for all applications.

Features:

– Pretreatment of oil to eliminate metal contaminants & residual p-contents

– Compact system ensure slurry preparation & bleaching in single reactor

– No carryover of bleaching chemical to Vacuum system

– Wet Bleaching with effective mechanical agitation

– Enhanced adsorption of coloring matters by bleaching earth

– Lower consumption of Bleaching earth

– Ensure accurate (Automated) dosing system of Bleaching earth

– Lower consumption of utilities

Edible oil refining is a complex process that involves various stages to purify and improve the quality of oils. One of the essential stages in edible oil refining is bleaching, which removes impurities and pigments from the oil. The bleaching reactor is used to remove pigments and other impurities from crude oils and fats, such as carotenoids, chlorophyll, oxidation products, soaps, trace metals, phosphatides, and polycyclic aromatic hydrocarbons. These impurities can affect the quality, stability and appearance of the refined oil products.

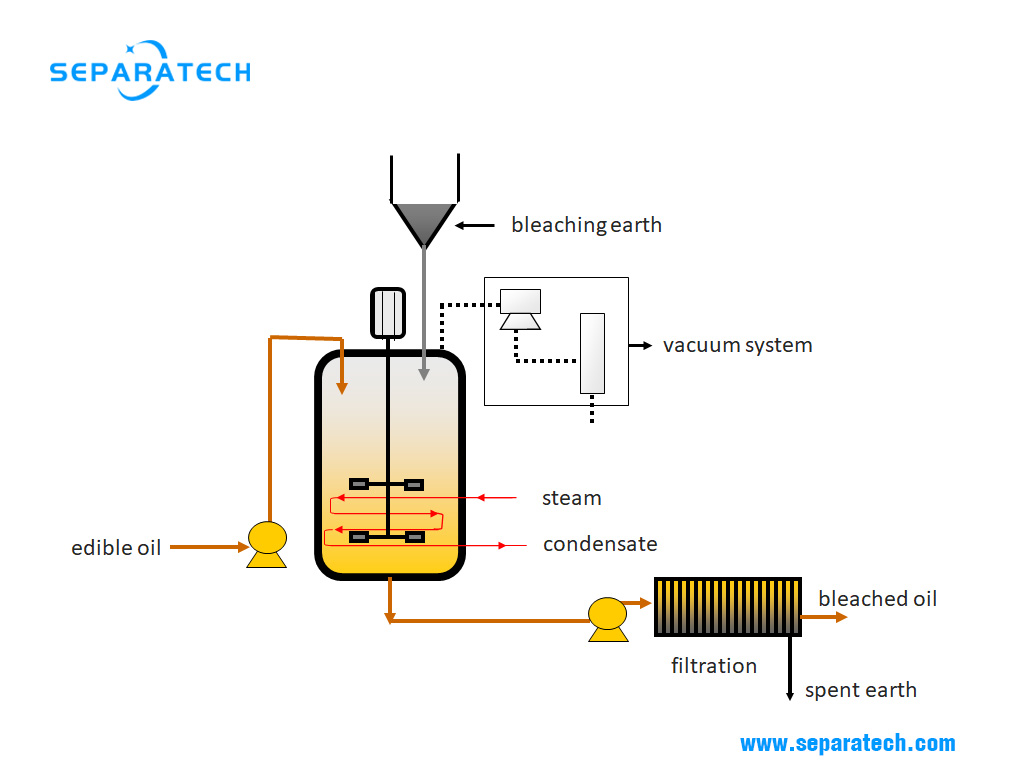

Bleaching refers to the process of adsorbing and removing unwanted impurities and colored matter from the crude oil under controlled conditions. This stage is critical because impurities and pigments not only affect the appearance of the oil but also its quality and shelf life. The edible oil bleaching process consists of mixing oil with bleaching agent, usually white clay or activated carbon, under controlled temperature and vacuum conditions. The bleaching agent adsorbs the impurities and then is separated from the oil by filtration. The bleaching reactor is designed to ensure optimal contact time and mixing efficiency between the oil and the bleaching agent. The bleaching process involves four main steps: mixing, heating, bleaching earth addition, and filtration.

The mixing of the crude oil and bleaching earth is done in the bleaching reactor. The bleaching earth is a type of clay that has the ability to adsorb impurities and pigments from the oil. The mixing process is done using agitators to ensure even distribution of the bleaching earth in the oil. The oil and bleaching earth mixture is then heated to a specific temperature, which can vary depending on the type of oil being processed. The heating process helps to activate the bleaching earth and enhance its adsorption capacity.

Once the bleaching earth is activated, it is added to the oil and mixed for several minutes. The bleaching process occurs when the impurities and pigments are adsorbed onto the bleaching earth particles. The bleaching earth is then separated from the oil using filtration. The filtered oil is then transferred to the next stage in the refining process.

In conclusion, the bleaching process is an important stage in edible oil refining, and SEPARATECH’s bleaching reactor plays a vital role in optimizing this stage. The design features of SEPARATECH’s bleaching reactor ensure the efficient and effective removal of impurities and pigments from the oil, resulting in high-quality and visually appealing edible oils. SEPARATECH’s bleaching reactor is a reliable and cost-effective solution for edible oil bleaching. It ensures high oil quality, maximized oil yield and minimized utility consumption. It is easy to operate and maintain with automated dosing and control.