Disc Stack Centrifuge

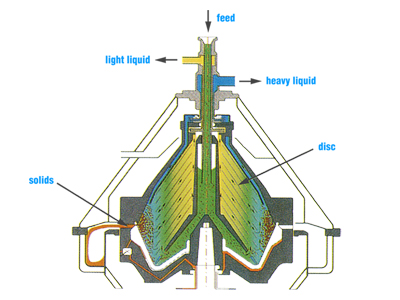

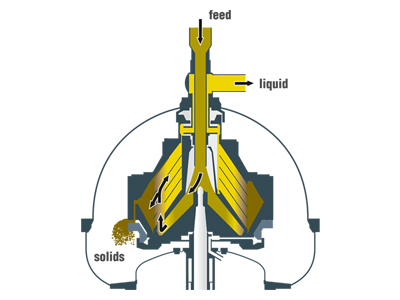

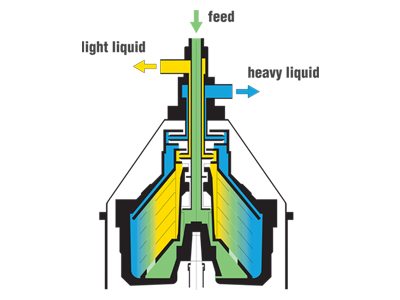

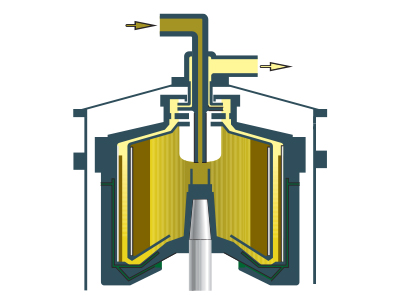

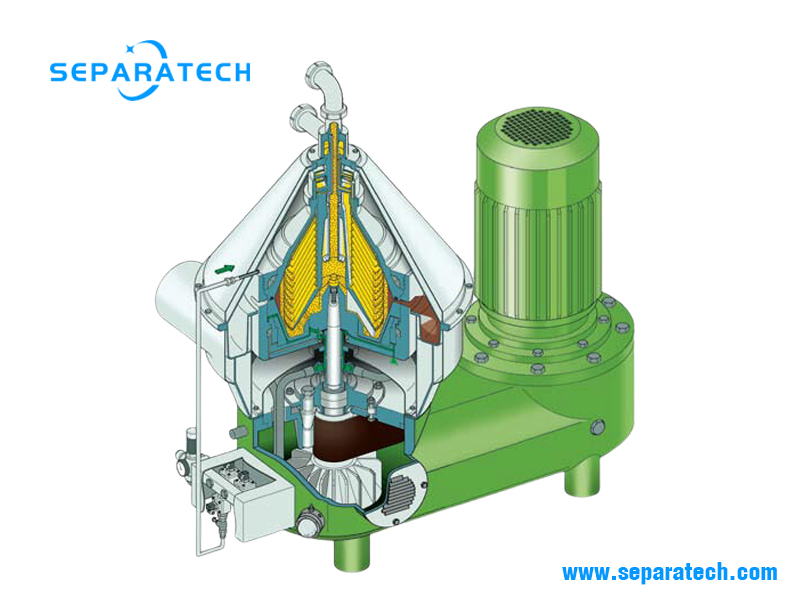

Disc stack centrifuge, also known as disk stack centrifuge, disc separator or disc bowl centrifuge, features a series of conical discs that splitting centrifugation space into thin layers. The disc stacks increase the surface settling area which speeds up the separation process.

The disc stack centrifuge is used to remove solids phase from liquid, or to separate two liquid phases from each other by means of an enormously high centrifugal force, which is higher than 10,000g in most cases.

The denser solids or liquids which are subjected to these forces move outwards towards the rotating bowl wall while the less dense fluids move towards the centre.

Different disc stack designs, arrangements and shapes are used for different processes depending on the type of feed present. The concentrated denser solid or liquid is then removed continuously, manually or intermittently, depending on the design of the bowl.

The disc stack centrifuge is very suitable for clarifying, concentrating, purifying products. Self-cleaning bowl, solids retaining bowl, nozzle bowl and chamber bowl are the most common design.

Basic principle of disc stack centrifuge

The basic principle behind a disc stack centrifuge is the separation of different components in a mixture based on their density difference. This is achieved by spinning a bowl containing the mixture at high speeds, which generates a centrifugal force that causes denser particles or liquids to move outwards towards the bowl wall while less dense fluids move towards the center.

A disc stack within the bowl contributes to higher separation efficiency by substantially increasing the separation area in the separator bowl. The conical discs in the stack create a series of narrow channels through which the fluid must pass. As the fluid moves through these channels, denser particles or liquids are forced outwards towards the bowl wall while less dense fluids move towards the center.

Once separated, the different components can be removed from the disc stack centrifuge for further processing or disposal.

Applications of disc stack centrifuge

– Beverage

Beer | Wine | Juice | Coffee | Tea | Soymilk

– Dairy

Skimming of milk and whey | Clarification of milk and whey | Bacteria removal from milk and whey | Concentration of cream

– Food

Oils and fats | Starch and protein

– Chemical

Organic chemical | inorganic chemical | petrochemical

– Pharmaceutical

Enzymes | Human vaccines | veterinary vaccines | Insulin from biomass | Human blood protein | Animal cell cultures

– Mineral oil

crude oil | residual oil | slop oil | fuel | lubricating oil | hydraulic oil | drilling fluid

– Environmental Technology

drinking water | municipal waste water | industrial waste water | sewage sludge