Solids Retaining Separator

Solids-retaining separator, also known as solid wall bowl centrifuge, features its solid wall bowl, or cylindrical bowl design. Compared with the self-cleaning separator, the solids-retaining separator with solid wall bowl is not able to periodically discharge the separated solids at full speed. Because there is no hydraulic system. So, all solids separated out shall be retained in the solid wall bowl, and it shall be removed manually. This is so called solids retaining separator.

Features of solids retaining separator

Solids-retaining separator is mainly designed for two purposes:

– Separating one liquid from another liquid

– Separating of trace solids from liquid (< 0.2% v/v)

they are used almost exclusively for the separation of liquid mixtures with no or a very small solids content since the separated solids can only be removed manually.

Because of the simplicity of the design, very high g force can be obtained, and the solids-retaining separator is thus very efficient in the recovery of fine particles.

Special material cladding such as Hastelloy C4/276 or Titanium are used to meet corrosion resistance specifications. The load-bearing parts, including bowl bottom and bowl top, can also be of complete super duplex material.

Working principle of solids retaining separator

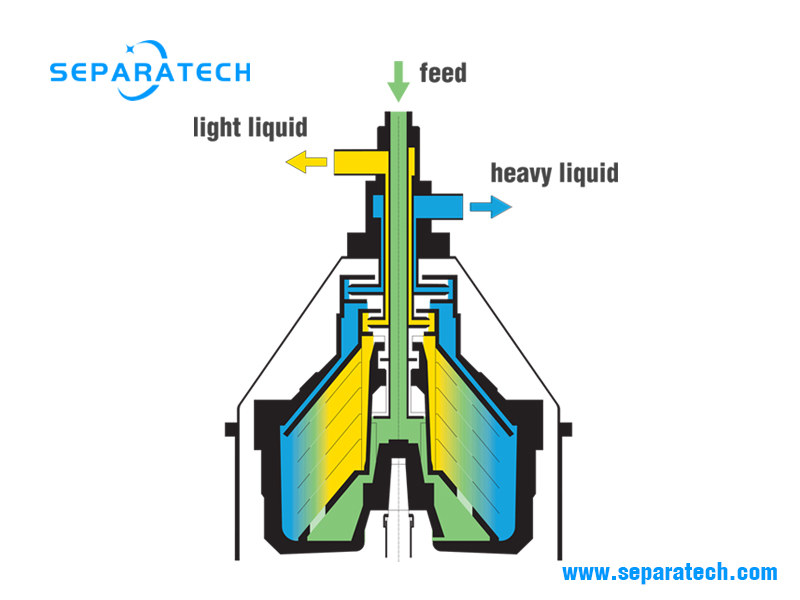

The product is fed into the solids retaining separator bowl through the feed pipe and into the distributor where it undergoes acceleration until it reaches the bowls rotating speed. The distributor then conveys the product to the rising channels of the disks stack where the separation between the heavy and light phases takes place. The disk stack, consisting of a large number of disks placed one above another, splits the liquid into thin layers, thereby reducing the settling distance for the solid particles.

The light liquid phase flows towards the centre of the bowl, from where it is pumped out of solids retaining separator under pressure for further processing.

The heavy liquid phase is led over a top disc into a chamber where an fixed or adjustable centripetal pump pumps it out of the solids retaining separator. The two pumps are surrounded by rotating liquid phases so, even if they are not rotating, they transfer the speed of the liquid into static pressure.

The solids phase is forced to and deposited at the periphery of the bowl. Separated solids is collected in the space at the periphery of the bowl and removed periodically manually.

Applications of solids retaining separator

Solids retaining separator, solids-retaining centrifuges of the stacked-disc or cylindrical-bowl design, has been widely used for :

– chemical products

– pharmaceutics

– dairy products

– lubricating oils

– fuel oils