Nozzle Separator

Nozzle separator is continuously operating disc centrifuge, for concentrating solids and clarifying liquids. Concentrated solids phase is discharged continuously through nozzles. Nozzle separators are built as centrifugal clarifiers and separators. they are more solids-orientated than self-cleaning separators. When they are configured to function as clarifiers, they are called concentrators. They are used to thicken solids from suspensions.

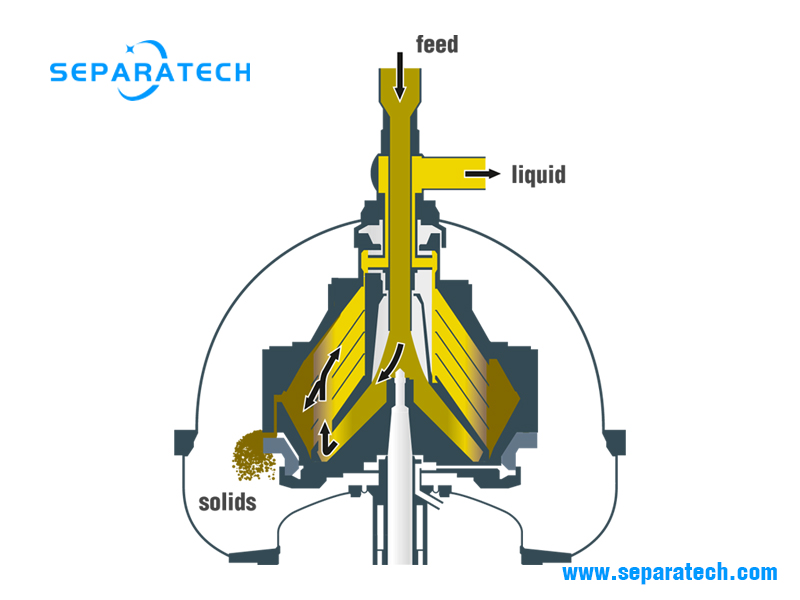

Working principle of nozzle separator

The products containing the liquid and the solids is introduced to the rotating nozzle centrifuge bowl from the top via a feeding pipe, and is accelerated in a distributor before entering the disc stack. Separation takes place between the discs. The disk stack, consisting of a large number of disks placed one above another, splits the liquid into thin layers, thereby reducing the settling distance for the solid particles. The light phase moves through the disc stack towards the centre of the nozzle separator bowl, and is discharged under pressure by a built-in centripetal pump. The heavy solid particles are collected at the bowl periphery and continuously discharged through the nozzles.

Features of nozzle separator

– Nozzle separator is able to handle high solids concentrations and viscosities.

– Nozzle separator is able to adjust the discharge concentration by using special nozzles.

– Nozzle separator is able to avoid shearing forces by using special structure.

– Nozzle separator is able to extend the centrifugal separating time in the bowl.

– Nozzle separator is able to prevent wear by using an innovative design of the separator bowl.

– Cleaning-in-place at operating speed

Standard equipment of nozzle separator

Nozzle separator with AC motor, control unit, special tools, speed and vibration sensors, oil pressure switch, vibration dampening feet, foundation plate and standard set of spares.

Conventional material data of nozzle separator

All parts coming in contact with the product are made of austenitic Cr-Ni-Mo steels or, in the case of highly stressed bowl parts, of martensitic Cr-Ni-Mo steels or duplex alloys.

Applications of nozzle separator

Nozzle separators are absolute specialists in the processing of fermentation products in biotechnology, the pharmaceutical and food industries.

The separated solids are discharged continuously through nozzles fitted at the bowl periphery. The nozzle separators are equipped with a hydraulically operated ejection system which enables both partial and total ejections to be triggered during product separation.

– Classification of solids by size

– Dewatering and washing of solids

– Clarification of liquids with high solids content

– Separation of two liquid phases and a solids phase

– Purification or concentration of substances like antibiotics, china clay, starches, yeasts, quark etc.

– Extraction of oil from oil sand or oil shale