Decanter Centrifuge

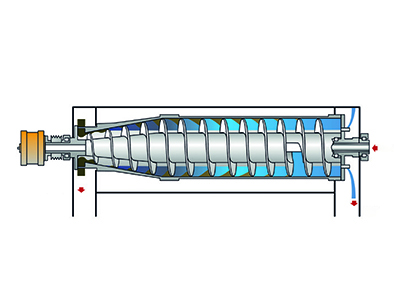

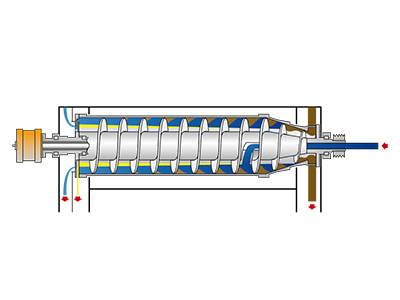

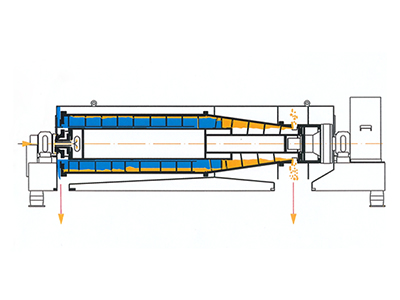

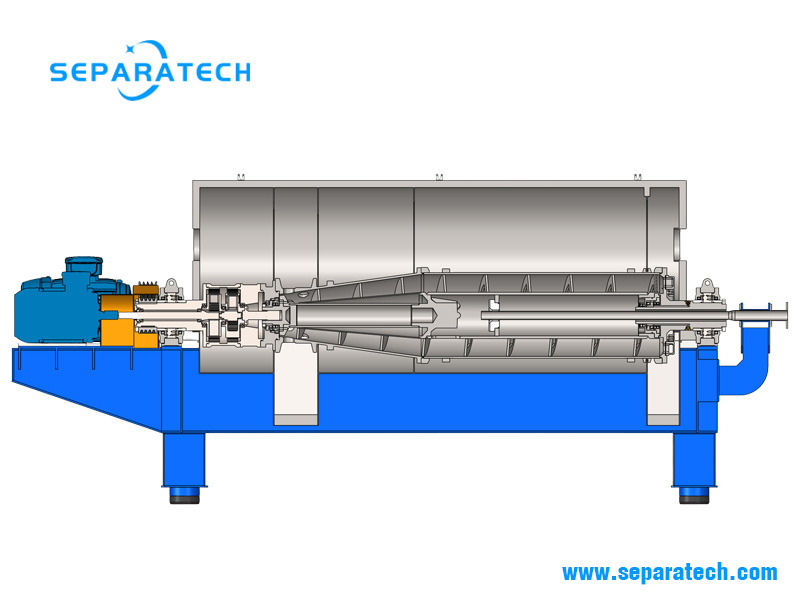

Decanter centrifuge, horizontal solid bowl decanter centrifuge, separates continuously solid materials from liquids in the suspension, or to separate two liquid phases from each other simultaneous removal of solids. Decanter centrifuges have been widely used for continuous separation of suspended solids from liquids, clarification of solids, classification of fine particles, etc.

According to the purpose of use, decanter centrifuges can be divided into the following three categories, Clarifying Decanter Centrifuge, Separating Decanter Centrifuge, Classifying Decanter Centrifuge.

Advantages of the Decanter Centrifuge

Continuous production, closed operation, high degree of automation.

Good for greasy sludges. The Decanter Centrifuge is excellent for dewatering or separation of fats, oils and greases.

Large capacity in small space. The Centrifuge can offer a large solids handling capacity in a very small space. This is advantageous in large plants.

With lower capture or high polymer dosage rate, can sometimes achieve higher cake solids than the belt press filter. One reason for this is the large amount of shearing as the sludge is moved through the machine, and the temperature increase in the sludge from the power energy dissipated. Increasing temperature improves dewatering. High G force centrifuges can create cell lysis and this releases extra liquid, but these liquids are high in odour, some of which is retained.

Typical Applications of Decanter Centrifuge

- Animal protein

Fish and meat by-product processing - Surimi processing

Edible protein recovery - Brewery

Recovery of extract, wort and yeast - Chinese medicinal materials, coffee and tea

Extraction of valuable components from Chinese medicinal materials, coffee and tea - Dairy

Recovery of casein, lactose, whey fines and cheese fines - Edible oil

Clarification of palm oil, olive oil and pressed seed oil - Juice

Extraction from fruit, berries and vegetables - Pectin

Recovery of extracted pectin - Vegetable protein

Extraction from soybeans, oil seeds and leguminous crops - Wine

Must and wine clarification

- Mineral industry

Kaolin clay and calcium carbonate processing, bentonite and titanium dioxide manufacturers - Oil exploration and petrochemical industry

Oil exploration, oil refineries and related industries, lubricating oil additives and waste oil stream recycling - Organic chemical industry

Organic intermediate and end products - Polymer industry

Thermoplastics including PVC, polypropylene, polystyrene, synthetic rubber and fibres - Inorganic chemical industry

Bleaching agents, acids, silica products and fertilizers - Ethanol production

Processing of grain alcohol spent wash and molasses fermenter residues - Starch processing

Based on wheat, maize, tapioca, cassava and potatoes - Waste recycling

Recovery and recycling of waste streams from the sectors listed above