Decanter Centrifuge Drive Type, decanter centrifuges stand as stalwarts in the realm of industrial separation, deftly separating solids from liquids with precision and efficiency. At the core of these machines lies their drive systems, the silent heroes powering their centrifugal prowess.

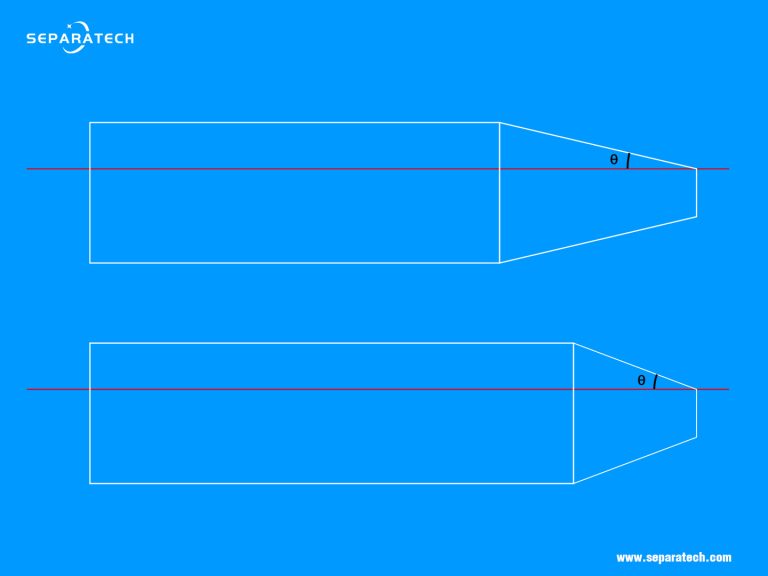

A decanter centrifuge requires a drive system, which is normally divided into two parts. The whole rotor must operate at a high rotational speed so that the solids are pushed against the inside wall of the bowl due to the centrifugal force. In addition, the scroll must rotate inside the bowl at a low rotational speed difference (differential speed) relative to the bowl. The differential speed determines the retention time of the solids in the bowl. This has a significant influence on the separation process. The solids are conveyed in the direction of the narrow bowl output.

Decanter centrifuges employ various drive configurations, each tailored to meet specific operational needs. There are four common drive types:

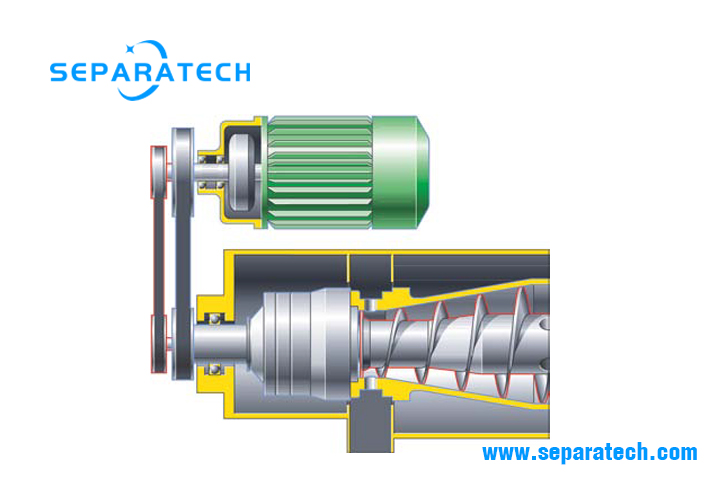

One Motor Drive:

– Simple yet robust, the one motor drive system features a single electric motor responsible for driving both the bowl and the scroll.

– A gearbox system facilitates the adjustment of speed ratios between the bowl and scroll, offering operational flexibility.

– Ideal for applications requiring straightforward operation and moderate speed control.

– Commonly found in industries such as wastewater treatment, food processing, and chemical manufacturing.

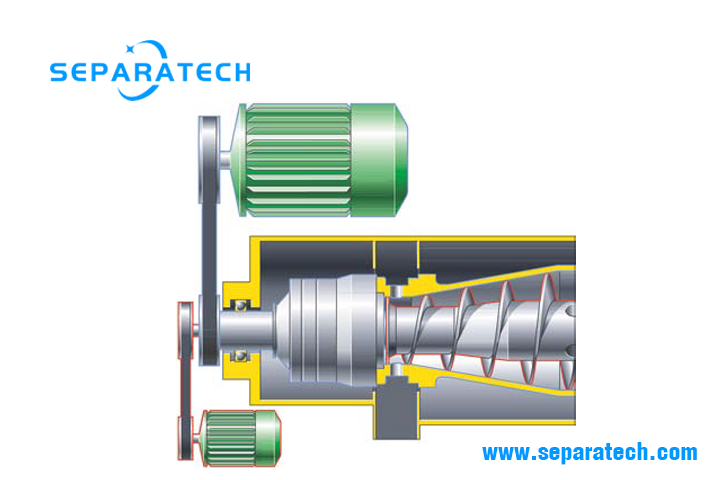

Two Motor Drive:

– This advanced system employs two separate electric motors—one dedicated to driving the bowl and the other to powering the scroll.

– Each motor is equipped with a Variable Frequency Drive (VFD), enabling independent control over bowl and scroll speeds.

– Offers precise customization of separation parameters, making it suitable for diverse feed materials and stringent separation requirements.

– Widely used in industries where fine-tuning of process parameters is essential, including pharmaceuticals, biotechnology, and petrochemicals.

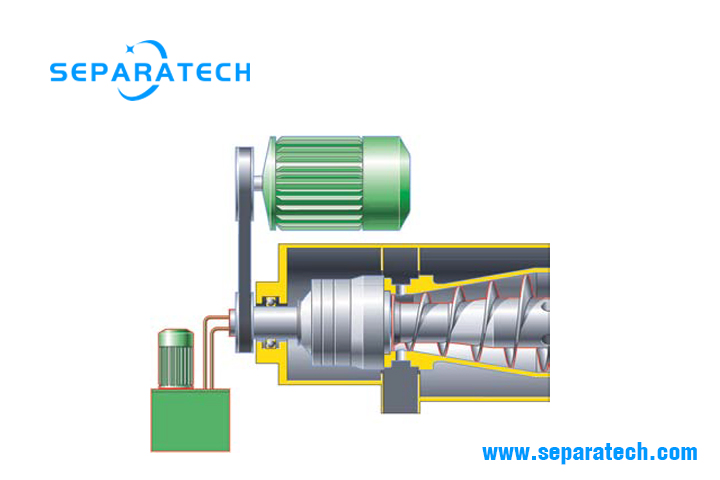

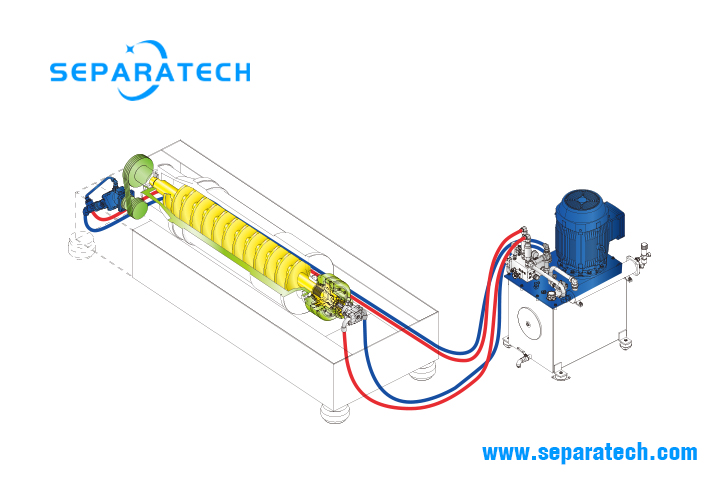

Half hydraulic drive:

– Combining the efficiency of electric motors with the torque prowess of hydraulic systems, the half hydro-drive configuration delivers optimal performance for specific applications.

– An electric motor drives the bowl via a gearbox, while a hydraulic motor powers the scroll.

– Well-suited for handling highly viscous materials and large bowl diameters, where torque and power are paramount.

– Commonly employed in industries dealing with drilling mud, mining slurries, and oil and gas production.

Full hydraulic drive:

– The pinnacle of decanter centrifuge drive technology, the full hydraulic drive system boasts independent hydraulic motors for both the bowl and the scroll.

– Offers unparalleled control over separation parameters, making it indispensable for processing highly demanding materials and operating at large scales.

– Preferred choice for heavy-duty applications such as wastewater dewatering, industrial wastewater treatment, and chemical processing plants.

Choosing the Right Drive Type for Your Needs

Selecting the optimal decanter centrifuge drive type hinges on several factors, including the nature of the feed material, desired separation efficiency, and operational requirements. Consulting with experienced engineers and manufacturers such as SEPARATECH can provide valuable insights into selecting the right drive system for specific applications.

Decanter centrifuge drive types play a pivotal role in determining the efficiency, versatility, and reliability of separation processes across various industries. By understanding the functionalities and applications of common drive configurations, operators can harness the full potential of decanter centrifuges to achieve optimal separation outcomes. Whether it’s the simplicity of a one motor drive or the precision of a full hydro-drive, each drive type offers unique advantages tailored to meet specific operational needs.