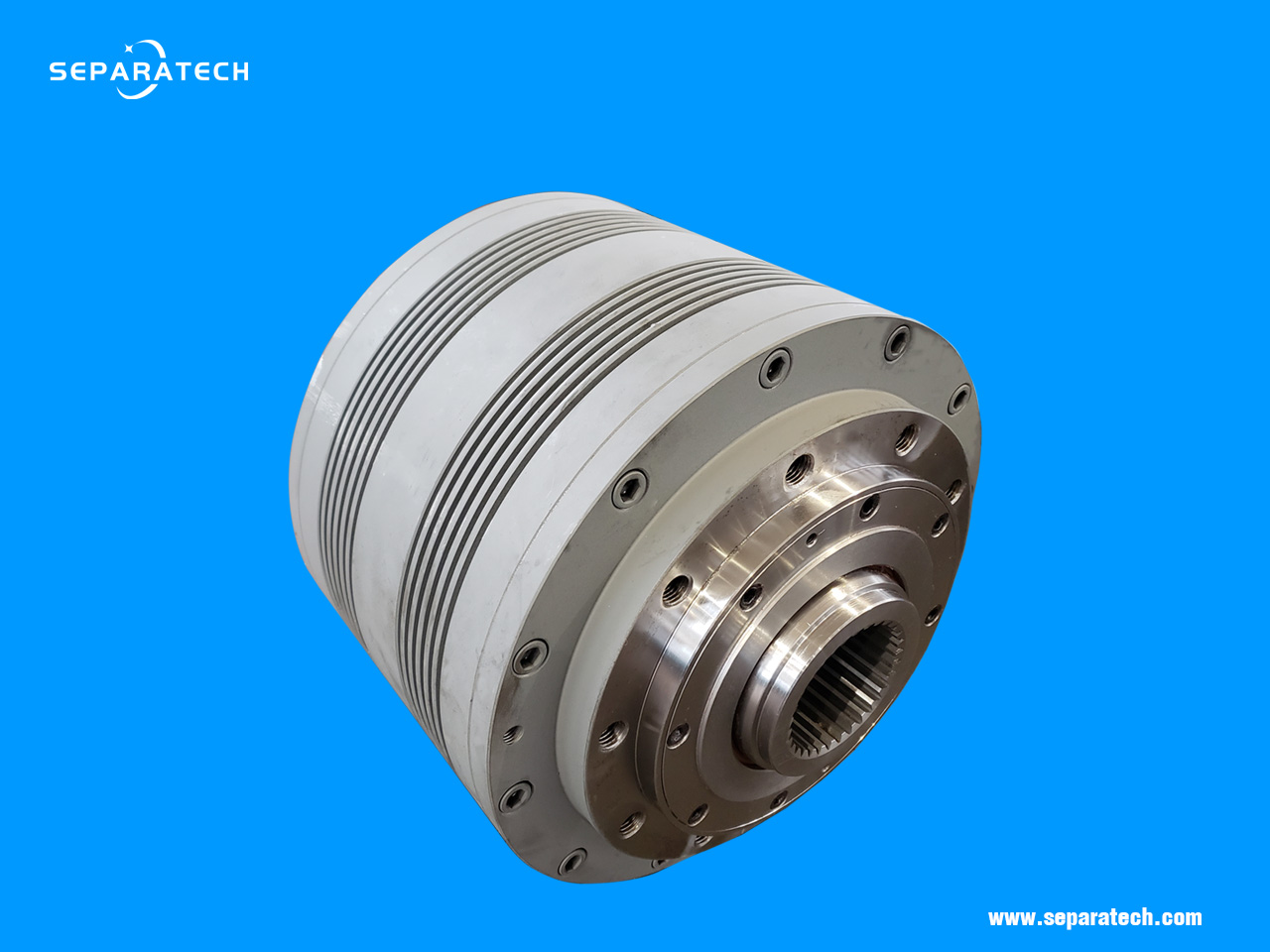

The two stage planetary gearbox in a decanter centrifuge is a critical component that plays a significant role in the separation processes within the machine.

Purpose and Function

The 2-stage planetary gearbox is an integral part of the decanter centrifuge’s drive system. Its primary purpose is to control the differential speed between the bowl and the conveyor within the centrifuge.

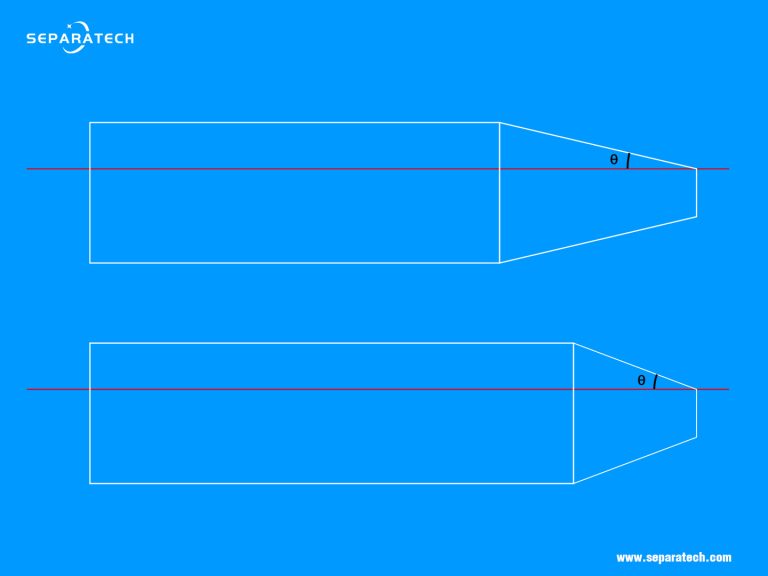

On a decanter the gearbox housing is mounted on the end hub thus running at the same speed as the bowl. Through stage one and two the drive shaft is connected to the conveyor which is driven in the same direction as the bowl but at a slightly lower speed (the differential speed). By varying the speed of the sunwheel shaft the conveyor speed and hereby the differential speed will vary.

This speed differential is essential for effective separation of solids from liquids. The gearbox ensures the centrifuge operates at the desired rotational speeds, optimizing separation efficiency.

Structure

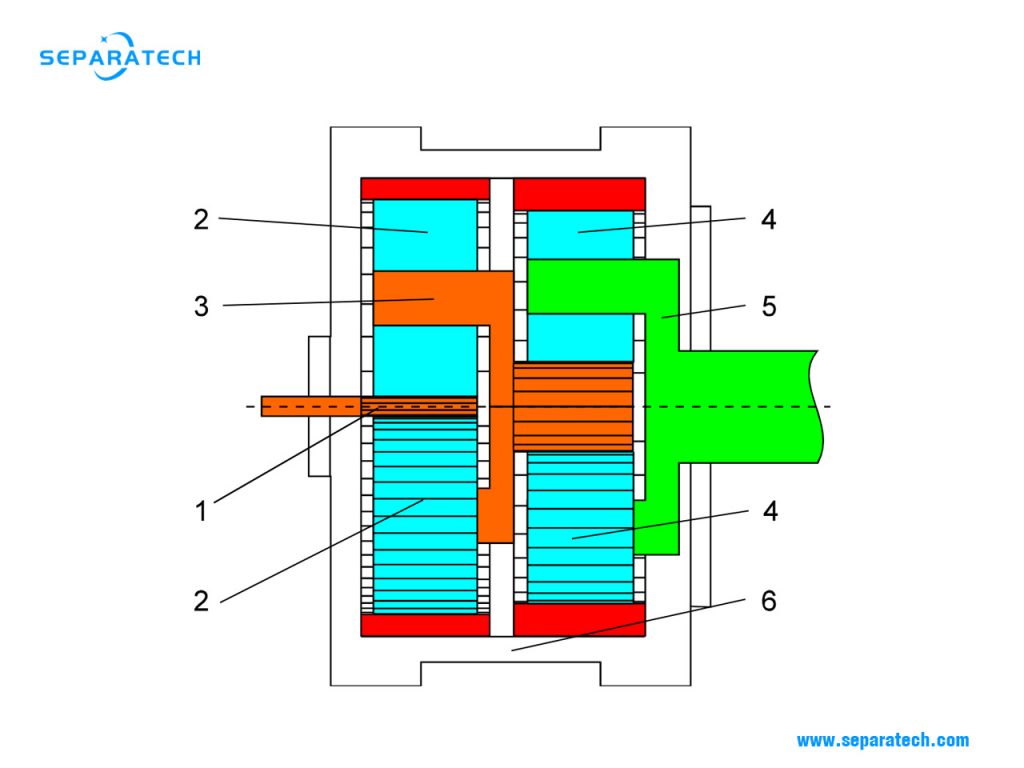

A two stage planetary gearbox consists of the main parts shown in figure. The 2-stage planetary gearbox consists of two key components:

a. Primary Stage Gearbox: The primary stage gearbox is connected to the main drive motor of the decanter centrifuge. It is responsible for transmitting power to the secondary stage and subsequently to the bowl of the centrifuge. The primary gearbox contains a large sun gear, ring gear, and planet gears, which create the first reduction stage.

b. Secondary Stage Gearbox: The secondary stage gearbox is connected to the primary stage gearbox and is responsible for driving the conveyor assembly. It is equipped with a second set of sun gear, ring gear, and planet gears, creating a second reduction stage. The output from this stage directly controls the conveyor’s speed relative to the bowl.

1: Sunwheel shaft, low torque

2: Planet gear wheels, low torque

3: Low torque planet wheel carrier

4: Planet gear wheels, high torque

5: High torque planet wheel carrier

6: Housing with ring gears

Working principle

When the sunwheel shaft (pinion) is rotated the planet wheels in the first stage will rotate. As the planet wheels are engaged into the ring gear in the housing, the planet wheel carrier will also rotate. The sunwheel on the planet wheel carrier makes the planet wheels in the second stage rotate and, like in stage one, the carrier rotates. This carrier is connected to the output shaft. The sunwheel shaft and the two carriers all rotate in the same direction. The housing is assumed to be at stand-still. The same will be the case even for a third carrier in case of a three-stage gearbox.

On a decanter the gearbox housing is mounted on the end hub thus running at the same speed as the bowl. Through stage one and two the drive shaft is connected to the conveyor which is driven in the same direction as the bowl but at a slightly lower speed (the differential speed). By varying the speed of the sunwheel shaft the conveyor speed and hereby the differential speed will vary.

Maintenance and Lubrication

Proper maintenance and lubrication are critical to ensuring the longevity and performance of the 2-stage planetary gearbox. Regular oil changes and inspections of gear wear are essential to prevent breakdowns and maintain efficient operation.

Advantages

The two stage planetary gearbox offers several advantages within a decanter centrifuge:

Precise Speed Control:

The two-stage design allows for fine-tuned control of the conveyor speed, which is crucial for maintaining the desired separation performance.

High Torque Transmission:

Planetary gearboxes can handle high torque loads efficiently, ensuring the centrifuge can process a wide range of materials effectively.

Compact Design:

The planetary configuration results in a compact and space-saving gearbox, making it suitable for installation in the limited space typically available in industrial settings.

Reliability:

Planetary gearboxes are known for their reliability and long service life, minimizing downtime and maintenance costs.

Two stage planetary gearbox parameters

| Designation | Transmission ratio | Rated torque (Nm) | Maximum speed (r/min) | Suitable bowl ID (mm) | Weight (Kg) |

|---|---|---|---|---|---|

| P2C2 | 95 | 1500 | 6000 | ≤300 | 45 |

| P2C3 | 57,90 | 4000 | 5000 | ≤400 | 70 |

| P2C4 | 57,90 | 6000 | 4000 | ≤500 | 90 |

| P2C5 | 32,47,59,90,105 | 7000~12000 | 3500 | ≤650 | 170 |

| P2C6 | 30,55,90 | 15000~20000 | 3000 | ≤700 | 250 |

| P2C7 | 38,50 | 25000 | 2500 | ≤800 | 280 |

| P2C8 | 40,47 | 35000~40000 | 2200 | ≤900 | 400 |

| P2C9 | 42,64 | 60000 | 2000 | 700 | |

| P2C10 | 41 | 90000 | 1800 | 950 |

Decanter Centrifuge Gearbox Customization

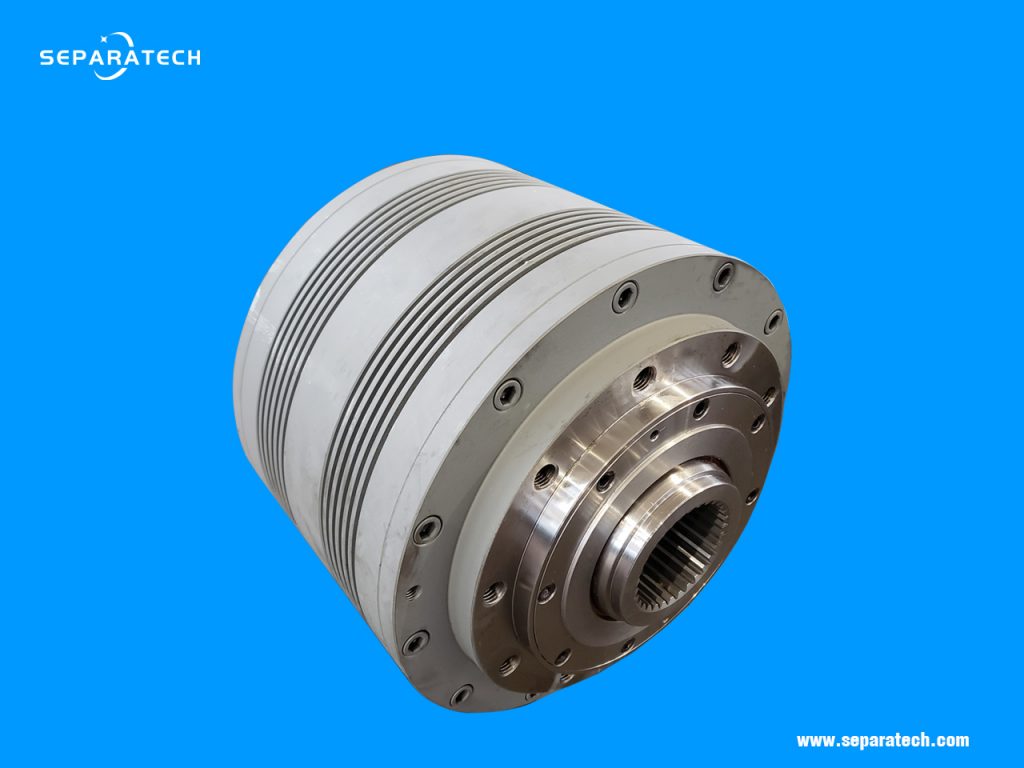

When it comes to centrifuge gearboxes, SEPARATECH is a name you can trust. Their expertise in customizing gearboxes to suit various industries is second to none. Whether you’re in the food, chemical, wastewater treatment, or any other industry that relies on decanter centrifuges, SEPARATECH has the solution for you.

With a commitment to precision, durability, and efficiency, SEPARATECH’s customized two stage planetary gearbox are designed to enhance your separation processes. They work closely with their clients to understand their unique needs and deliver gearboxes that surpass expectations.

In conclusion, centrifuge gearboxes are the unsung heroes that drive the efficiency and effectiveness of decanter centrifuges. Understanding their structure, working principle, and key characteristics is essential in appreciating their role in the world of separation processes. When it comes to customized centrifuge gearboxes, SEPARATECH stands out as the trusted partner to meet your specific needs.

Investing in a high-quality, customized centrifuge gearbox from SEPARATECH is not just a wise choice; it’s a step towards enhancing your operational efficiency and overall success.

Ready to experience the power of SEPARATECH’s customized decanter centrifuge gearboxes? Contact them today and unlock the potential of your separation processes.