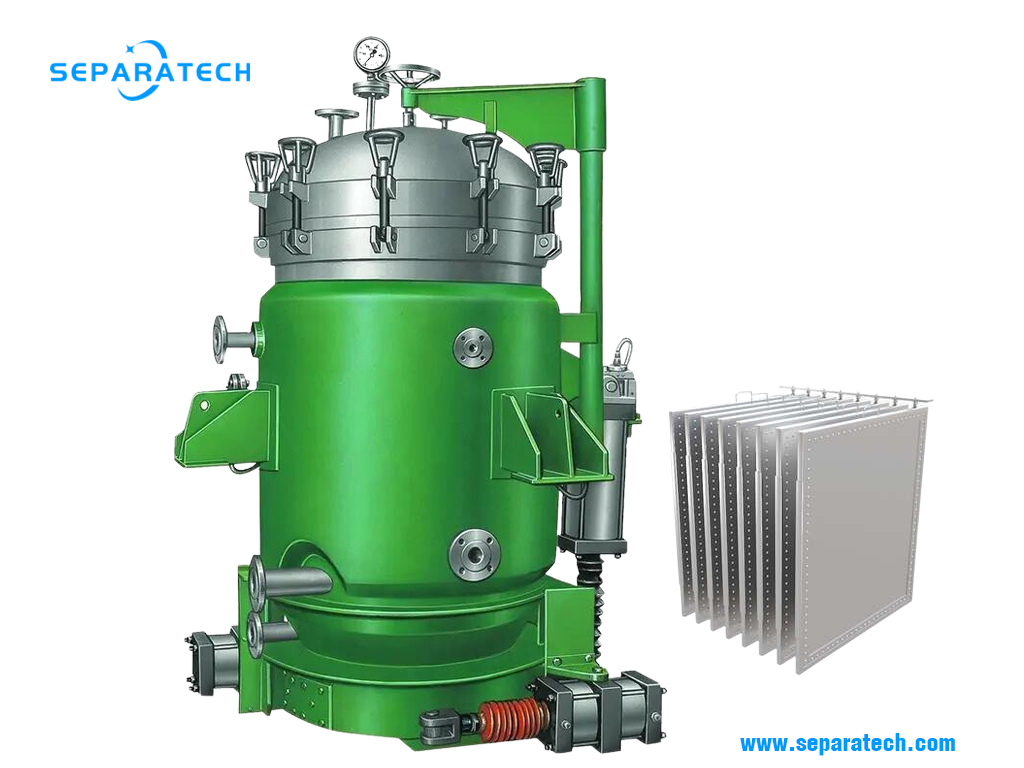

Vertical pressure leaf filter with quick-opening bottom

As an original manufacturer of pressure leaf filter, SEPARATECH has extensive experience with various types of vertical and horizontal pressure leaf filters. We know how important it is to choose the right filter for different applications and conditions. That’s why we are excited to share with you a new product that has been recently launched to the market: the vertical leaf filter with hydraulic quick-opening bottom.

This innovative filter is based on the conventional vertical leaf filter, but with a significant improvement: it has a hydraulic quick-opening bottom that allows for easy and fast discharge of the filter cake. This feature gives it several advantages over the traditional vertical leaf filter with a conical bottom, especially for materials that have high solid content, high viscosity, or high temperature. Let me explain how.

First, for materials that have high solid content, such as sludge, clay, or metal powder, the vertical leaf filter with hydraulic quick-opening bottom can achieve a higher efficiency of unloading the filter cake. This means that the filter cycle time is reduced, and the actual production capacity is increased. Compared to the conventional vertical leaf filter, which may require manual scraping or vibration to remove the filter cake, the hydraulic quick-opening bottom can discharge the filter cake in seconds with a simple push of a button.

Second, for materials that have high viscosity, such as resin, oil, or honey, the vertical leaf filter with hydraulic quick-opening bottom can effectively avoid the difficulty of unloading the filter cake caused by high viscosity. As you may know, high viscosity materials tend to stick to the filter leaves and form a thick layer of filter cake that is hard to remove. This can lead to low filtration efficiency, frequent cleaning, and even filter blockage. The hydraulic quick-opening bottom can solve this problem by applying a strong hydraulic force to break and discharge the filter cake, without damaging the filter leaves or affecting the filtration quality.

Third, for materials that have high temperature, such as asphalt, wax, or molten metal, the vertical leaf filter with hydraulic quick-opening bottom can overcome the limitation of the traditional valves that rely on rubber valve rings for sealing. As you may know, rubber valve rings have a low resistance to high temperature and may deform or melt when exposed to temperatures above 150°C. This can cause leakage, contamination, or damage to the valves and pipes. The hydraulic quick-opening bottom does not use any rubber valve rings, but instead uses a metal-to-metal sealing mechanism that can withstand high temperatures and pressures without compromising the sealing performance.

| Designation | Filtration area(m2) | Pressure(bar) | VPFBolume(L) | Weight(Kg) | Dimension(mm) |

|---|---|---|---|---|---|

| VPFB-5 | 5 | 5 | 600 | 2100 | 1500×1300×1950 |

| VPFB-7 | 7 | 5 | 780 | 2500 | 1600x1400x2000 |

| VPFB-10 | 10 | 5 | 1200 | 2800 | 1700×1500x2320 |

| VPFB-15 | 15 | 5 | 2000 | 3800 | 2050x2100x1900 |

| VPFB-20 | 20 | 5 | 2200 | 4200 | 2050×2100x2200 |

| VPFB-25 | 25 | 5 | 2500 | 4500 | 2050x2100x2600 |

| VPFB-30 | 30 | 5 | 4700 | 5800 | 2600x2500x3600 |

| VPFB-35 | 35 | 5 | 4900 | 6500 | 2600×2500×3800 |

As you can see, the vertical pressure leaf filter with hydraulic quick-opening bottom is a superior product that can offer you many benefits over the conventional vertical pressure leaf filter. It can improve your filtration efficiency, reduce your maintenance costs, and extend your equipment life span. If you are interested in learning more about this product or want to order one for your own application, please contact us directly, We would be happy to answer any questions you may have and provide you with a free quote.