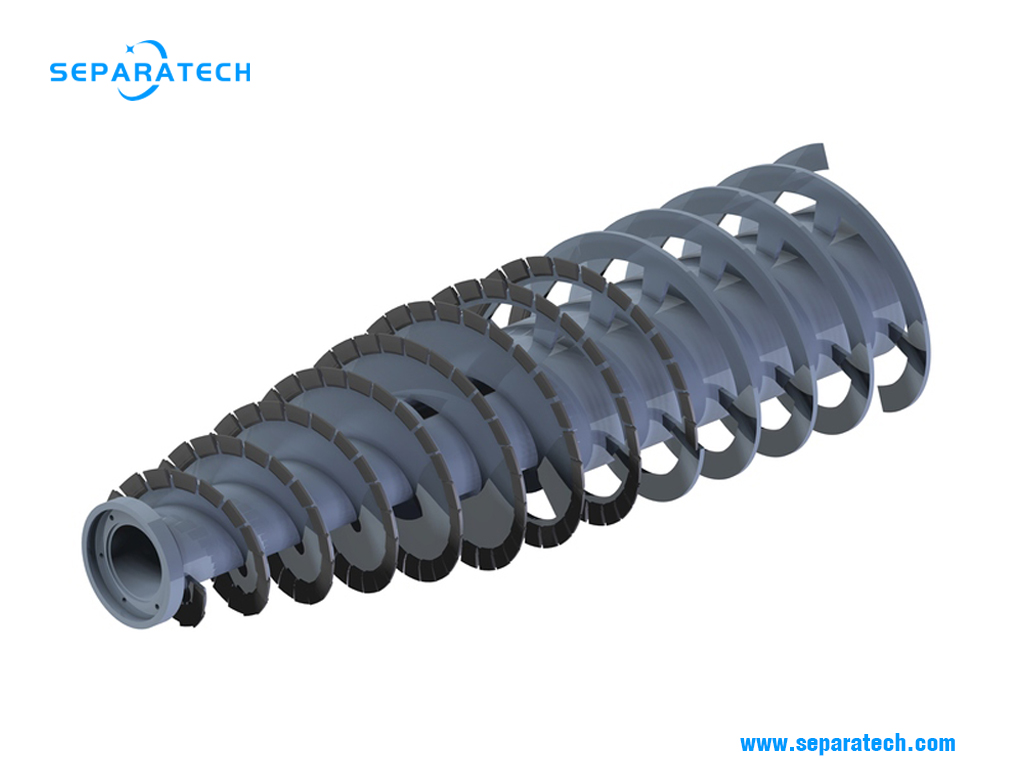

Scroll Conveyor of Decanter Centrifuge

SEPARATECH provides OEM scroll conveyor of decanter centrifuge, reverse engineer and optimize all decanter centrifuges for any decanter centrifuge brand.

Our experience makes all the difference for accurate and durable scroll conveyor of decanter centrifuge manufacturing.

The scroll conveyor, conveyor screw, is in the form of an Archimedean screw. fitting inside the beach and bowl between the two end hubs. with a small clearance of less than 2 mm radially. It has a number of functions. Not only does it convey the solids, after they form a cake. along the cylindrical bowl section and up the beach, it also accepts the feed and accelerates it up to bowl speed.

In its simplest form, the scroll conveyor has a cylindrical central hub with a set of flights welded onto it, to form one continuous helix. The conveyor screw bearings and associated seals are housed in both ends of its central hub. Somewhere in between the bearings will be a chamber called the feed zone, sealed and isolated from both bearings.

Conveyor flights are available in a variety of configurations. The flights may be single lead or double lead. The pitch may be fine or coarse, the flights may be perpendicular to the centre line or they may be canted (inclined).

The traditional conveyor design has helical flights without any cut-out (full flight).Some conveyors are quasiaxial flow conveyors, i.e. conveyors with openings named windows in the flights near the conveyor hub allowing liquid to flow in an axial direction. This type of conveyor is mainly used in applications where the layer of sedimented solids is kept very deep in order to achieve the highest possible dry matter content. This leaves little room for the liquid which can ‘escape’ through the windows. Windows are often used in connection with a baffle disc. Some conveyors have a double cone. By reducing the flight height in the area around the cone-cylinder intersection solids conveying is enhanced and wear is reduced in several applications.