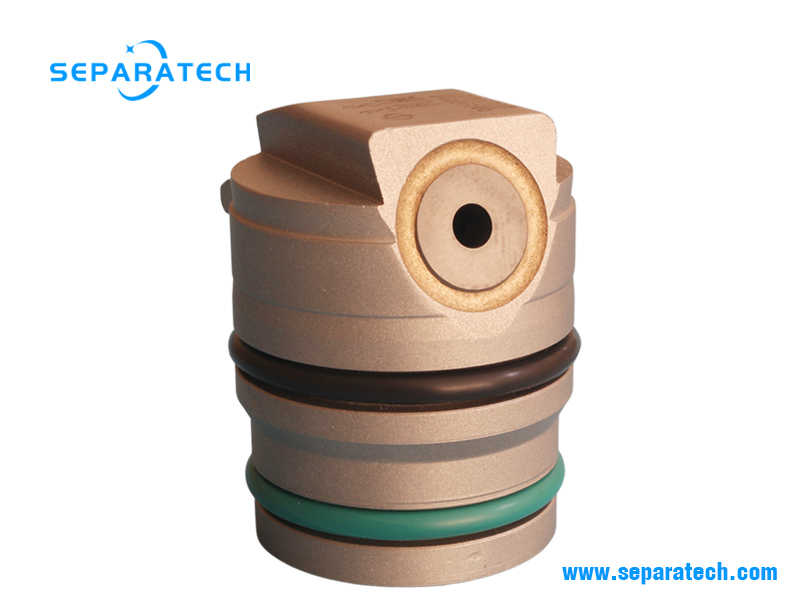

Disc Centrifuge Nozzles

Disc centrifuge nozzles are one of the important parts of the disc nozzle centrifuge. Its main function is to continuously discharge the sediment inside the bowl, such as starch, after being concentrated.

For the nozzle centrifuge, the geometric structure design of the nozzle is not only related to the separation effect of the centrifuge, but also related to the energy consumption of the nozzle centrifuge. At the same time, the material of the nozzle directly determines the durability of the nozzle. Disc centrifuge nozzles made of high-density carbide tend to be more durable than ordinary nozzles. Of course, the brazing process in the manufacturing process of the disc centrifuge nozzles also directly determines the quality and separation effect of the nozzle separator.

After more than 10 years of uninterrupted research and development and application, the disc centrifuge nozzles of SEPARATECH not only have a separation effect comparable to the original nozzle of the centrifuge, but also has a service life of the nozzle that has reached the first-class level in this industry. With its excellent energy-saving features, it do save a considerable amount of electricity bills for the centrifuge users every year.

Features:

– Excellent separation performance, including both starch and gluten concentration

– Long service life, high durability

– Power saving

3384‑6710‑040 NOZZLE COMPL

3384‑6710‑110 NOZZLE COMPL

3391-6710-250 NOZZLE COMPL

Nozzles of SEPARATECH have been widely installed on SDA / SDC series nozzle centrifuges, and have been well received by users. They are an excellent alternative of the 3384‑6710‑040 NOZZLE COMPL , 3384‑6710‑110 NOZZLE COMPL and 3391-6710-250 NOZZLE COMPL.

Nozzle centrifuge for starch processing

The nozzle centrifuges have been widely used in the starch industry for processes that include primary starch separation, gluten thickening, millstream thickening and middling concentration.

They are also used for classifying, concentrating and washing solids, and for clarifying liquids that contain relatively high solids concentrations.

Easy maintenance

Improved disc centrifuge nozzles make your starch nozzle separator easier to maintain than before. Convenient to install and remove, the new disc separator nozzle reduces the amount of time and labor required for routine maintenance. The nozzles provide extra protection and minimize the risk of damage to the bowl wall.