What Is an Olive Oil Centrifuge?

An olive oil centrifuge is a specialized piece of equipment designed to separate the valuable olive oil from the fruit’s water and solid particles. Unlike traditional pressing methods, centrifuges use high-speed rotation to exploit the difference in density between oil, water, and solids. The result is faster processing, higher yields, and superior oil quality.

Olive oil centrifuge separator for virgin olive oil extraction

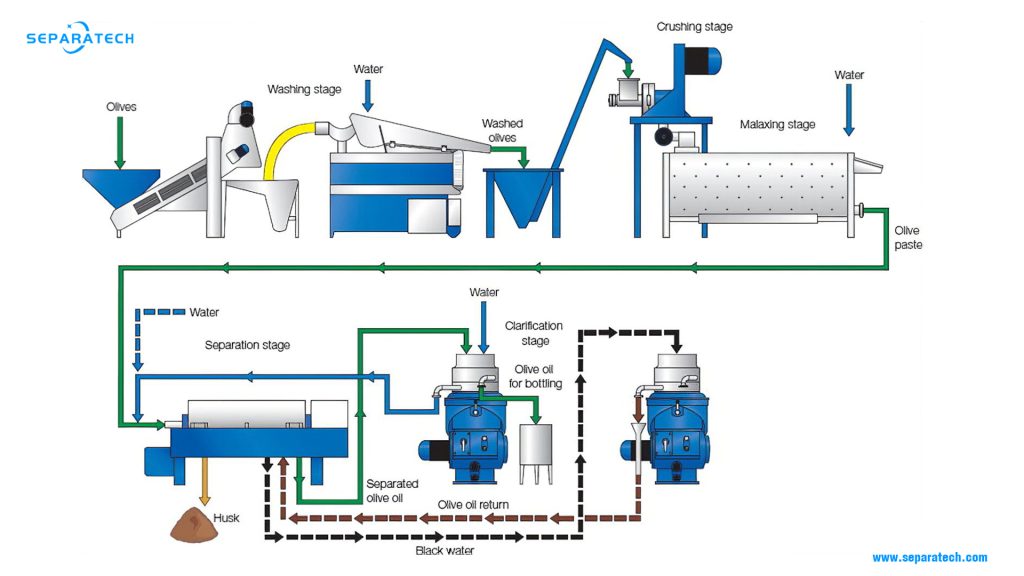

The production of virgin olive oil involves several carefully controlled steps to ensure high quality, purity, and preservation of natural flavors. The process can be summarized as follows:

1. Reception and Washing Stage

Freshly harvested olives are delivered to the plant and conveyed to the washing system. Here, leaves, twigs, and dirt are removed, and the olives are thoroughly washed with water. The result is clean, washed olives, ready for processing.

2. Crushing Stage

The washed olives are passed through a crusher, where they are broken down into a fine paste. This olive paste contains oil, water, and solid components (skin, pulp, and stone fragments).

3. Malaxing Stage

The olive paste is then slowly mixed in a malaxer. During this stage, small oil droplets begin to merge into larger drops, improving oil separation efficiency in the following steps. Sometimes, water is added to help the process.

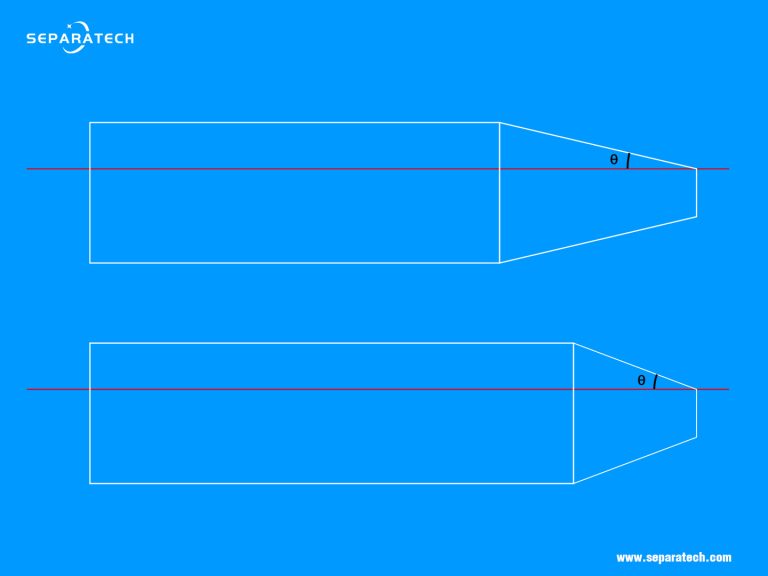

4. Separation Stage (Decanter Centrifuge)

The olive paste is transferred to a horizontal decanter centrifuge, where centrifugal force separates the components based on their densities:

Olive oil (lightest fraction)

Vegetation water (black water)

Solid husk (pomace)

This is the primary extraction step that yields crude olive oil.

5. Clarification Stage (Vertical Separator)

The crude olive oil is directed into a vertical centrifuge (olive oil centrifuge). This machine removes fine particles, moisture, and impurities that remain after decanting. The result is pure, clarified olive oil.

6. Storage and Bottling

The clarified virgin olive oil is collected and stored in stainless steel tanks under controlled conditions to preserve quality. Finally, it is packaged and bottled as Virgin Olive Oil or Extra Virgin Olive Oil, depending on its quality and chemical/organoleptic parameters.

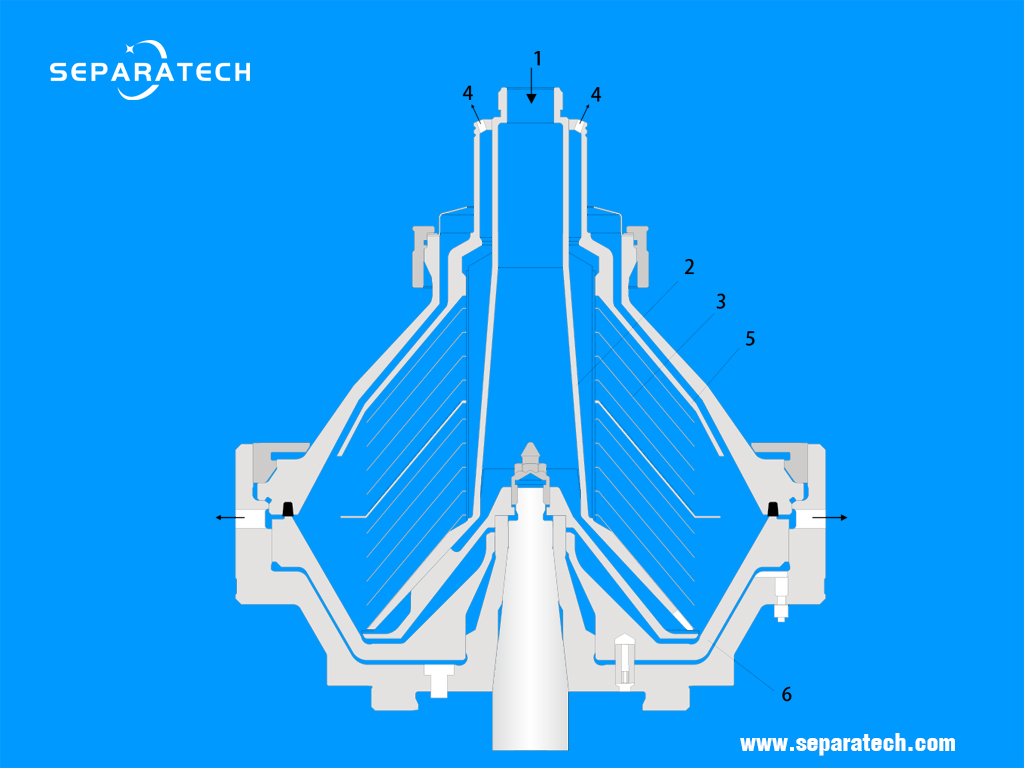

How Does olive oil centrifuge Work?

Separation takes place inside a rotating bowl. The crude olive oil is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe, and is accelerated in the distributor, which is specially designed to ensure smooth acceleration of the feed liquid. Leaving the distributor, the oil enters the disc stack. The separation of oil-water-solids takes place between the discs, with the oil phase moving through the disc stack to the center and is discharged into the upper collecting frame.

The water and heavy solids separated from the oil moves out to the periphery, the water is led via channels in the top disc to the lower collecting frame.

The solids are collected in the periphery, from where it is discharged intermittently into the solids collecting cover below the bowl. The solids discharge is achieved by a hydraulic system which at preset suitable intervals forces the sliding piston to drop down and thus opening the ejection ports at the bowl periphery. Solids ejection is initiated by a control unit.

Advantages of Olive Oil Centrifuges

Switching from traditional presses to centrifuges offers multiple benefits for olive oil producers:

• Higher efficiency – Continuous operation with reduced downtime.

• Improved oil quality – Less oxidation and contamination during extraction.

• Scalability – Suitable for small farms as well as large-scale industrial plants.

• Better by-product management – Easier handling of pomace and wastewater.

Technical specifications

| Designation | Throughput capacity | Bowl speed | Motor power | Weight |

|---|---|---|---|---|

| OVS40 | 5000 HPL | 7000 rpm | 11 Kw | 1200 Kg |

| OVS60 | 10000 HPL | 6700 rpm | 18.5 Kw | 1600 Kg |